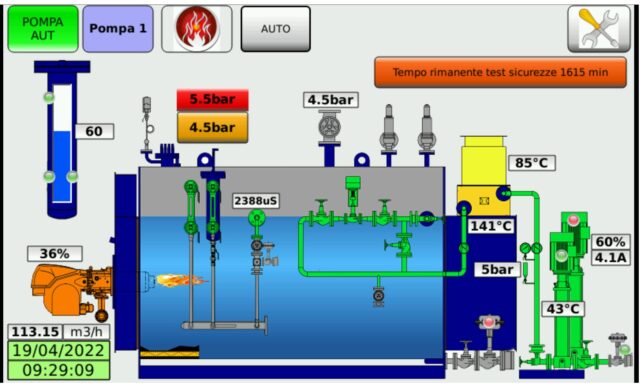

The Industry 4.0 system developed in collaboration with BBS Division is capable of remote control and monitoring of all the data and signals coming from the equipment installed on the boiler. This gives the opportunity of optimising the productive process and bring down wastes of recources and money.

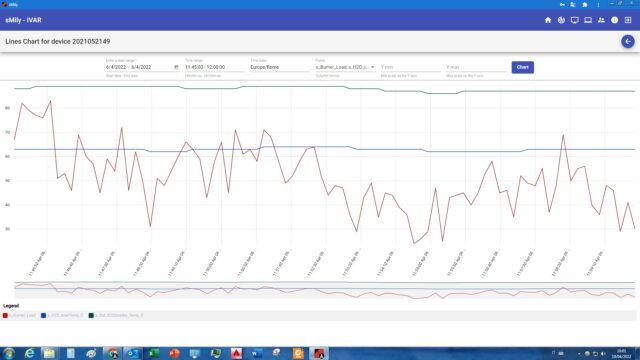

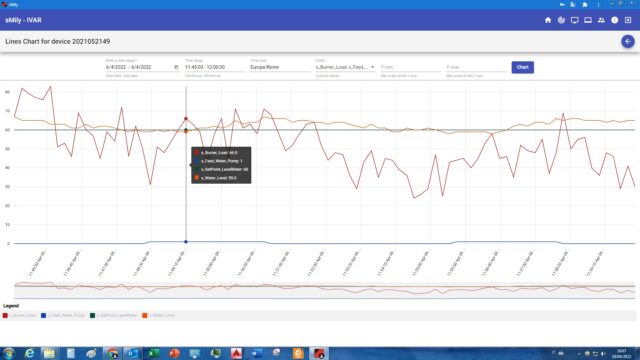

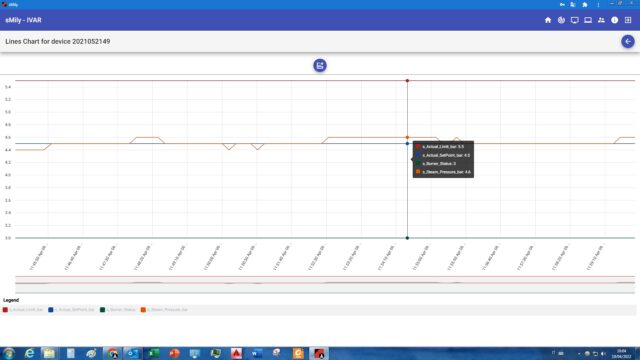

With the connection via ModBus either via LAN cable or Wifi and the use of a VNC, the boiler can be controlled from anywhere in the world and it can generate grapghs to better analyze how the boiler works. We can monitor steam pressure, water level, burner modulation, smoke and water temperatures and more. The SaveAll system can also calculate how much steam is being produced or how much fuel is being consumed without having to mount expensive flow-rate transmitters or fuel-rate counters. All of the signals can also be integrated in an already-existing Managment system via addresses.

It advises you when to stop the boiler for maintenence, it runs automatically based on a weekly timer and it offers the possibility of remote assistance which, given the current travelling restriction due to the Covid-19 pandemic, it can bring down the intervention time and the assistance costs.

Click here for more information: https://www.ivarindustry.it/wp-content/uploads/Brochure-tecnica-sistema-4.0-Ivar-BBS.pdf

Click here for BBS Division article: https://www.bbsdivision.com/en/it-is-savealls-birthday-the-adaptable-software-for-steam-generators-and-boilers-is-now-one-year-old/